-

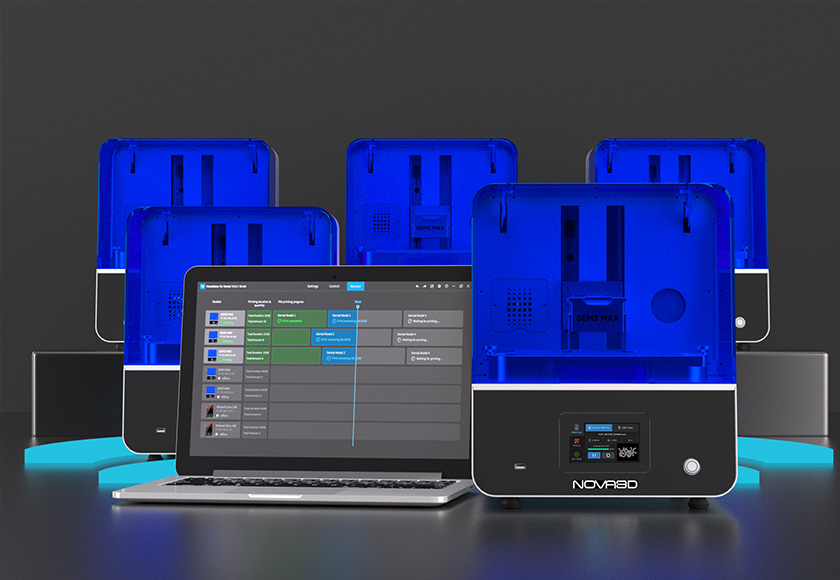

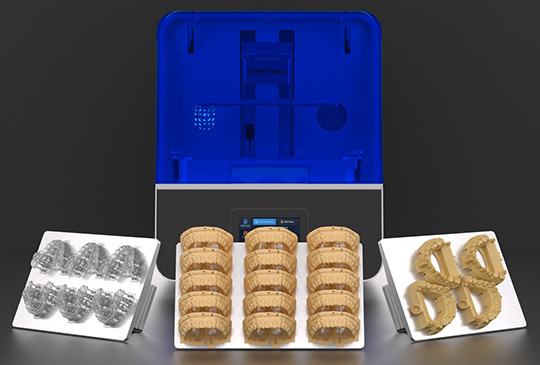

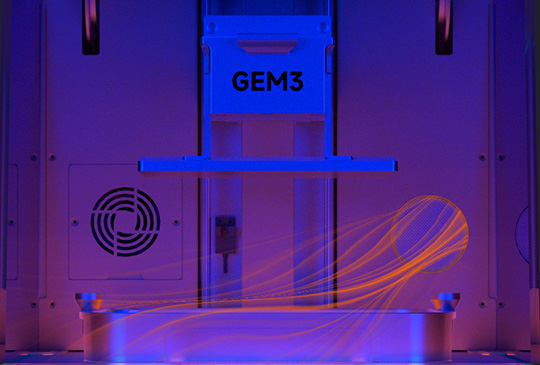

3D Printer

-

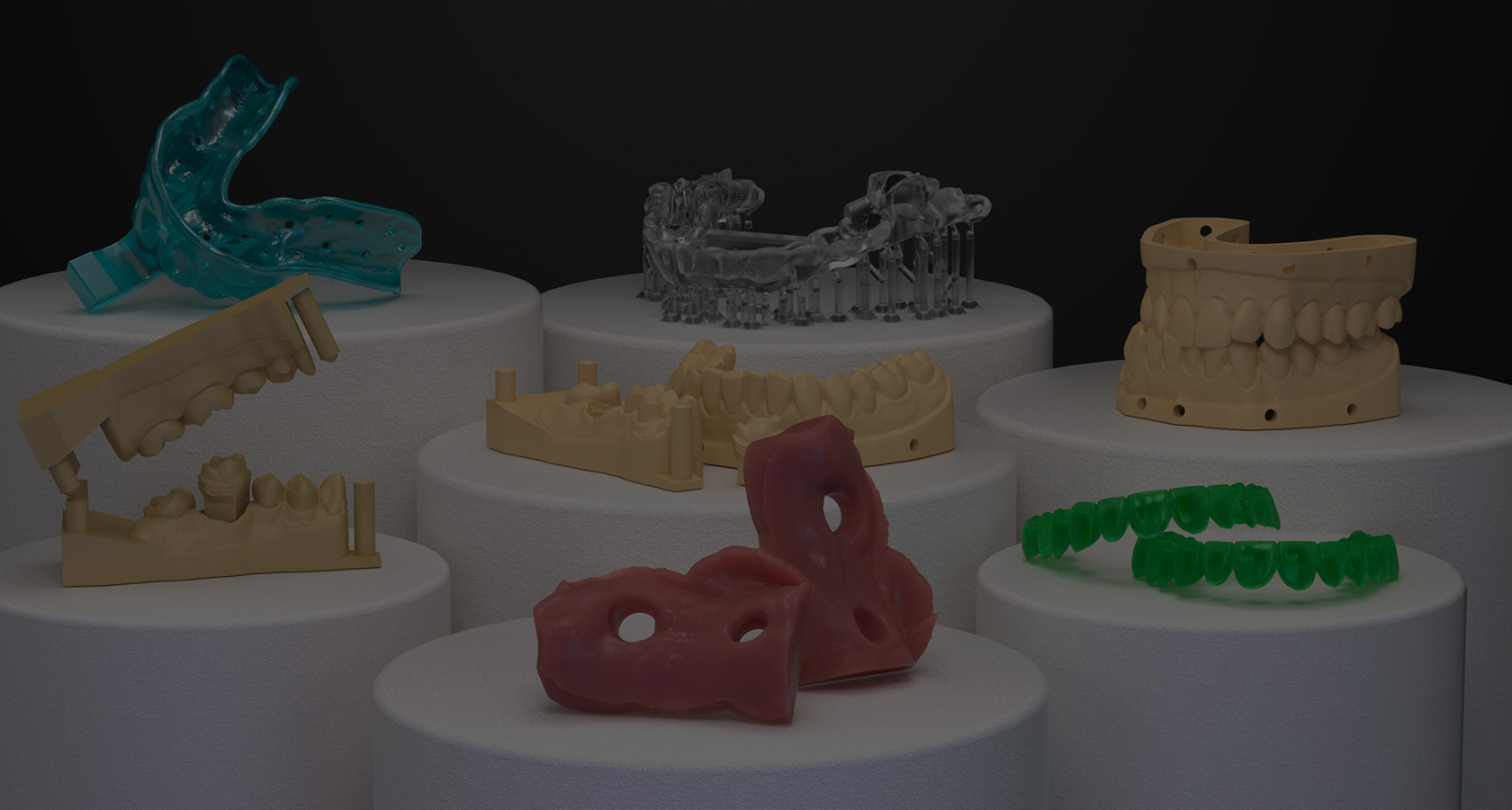

Material

-

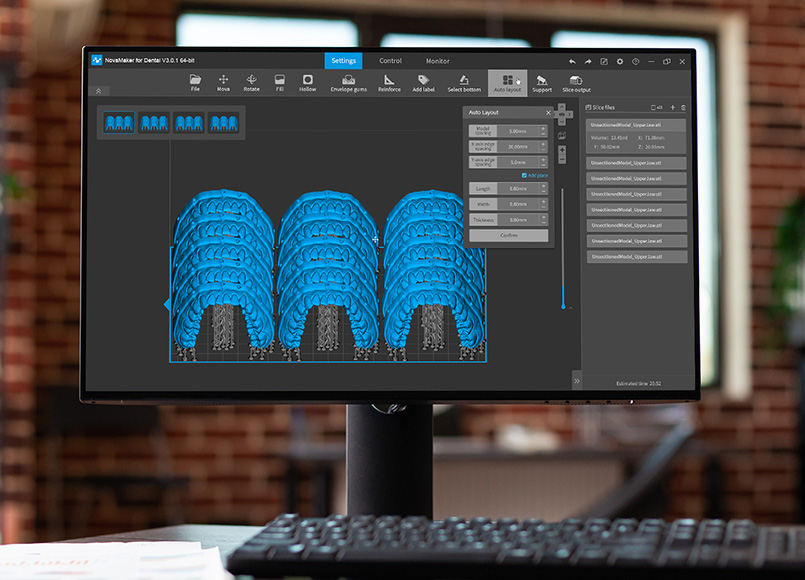

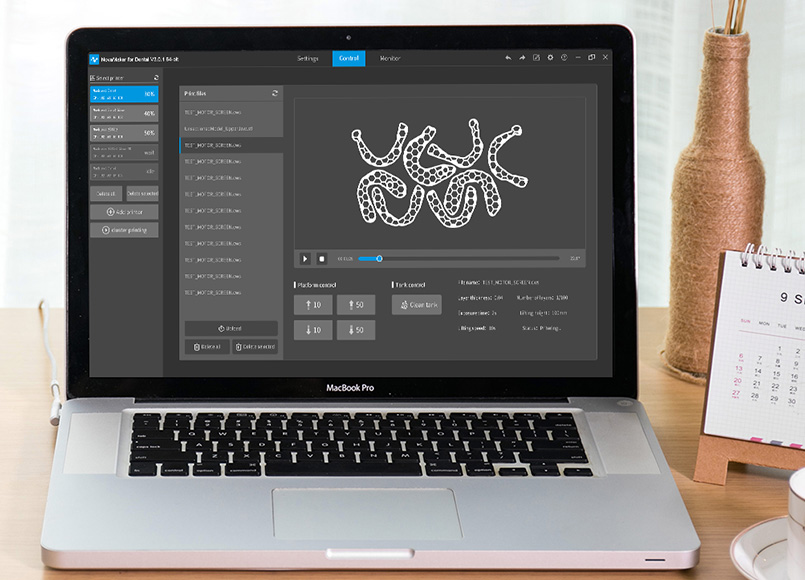

Software

-

Application

-

Support

Download NovaMaker (Windows)

Download NovaMaker (macOS)