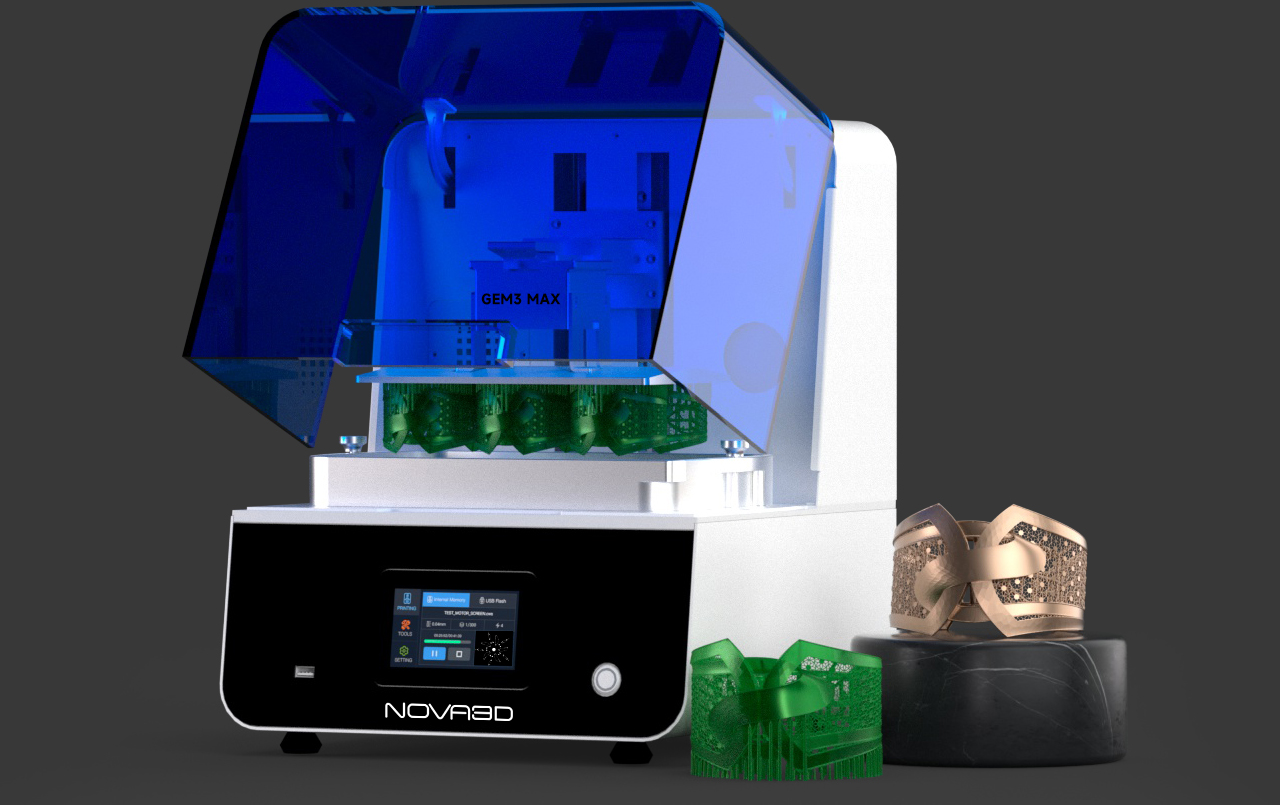

GEM3 MAX

Precision at Scale, Crafted for Excellence

Craft Flawless Creations, Unveil a New Chapter in Jewelry Craftsmanship!

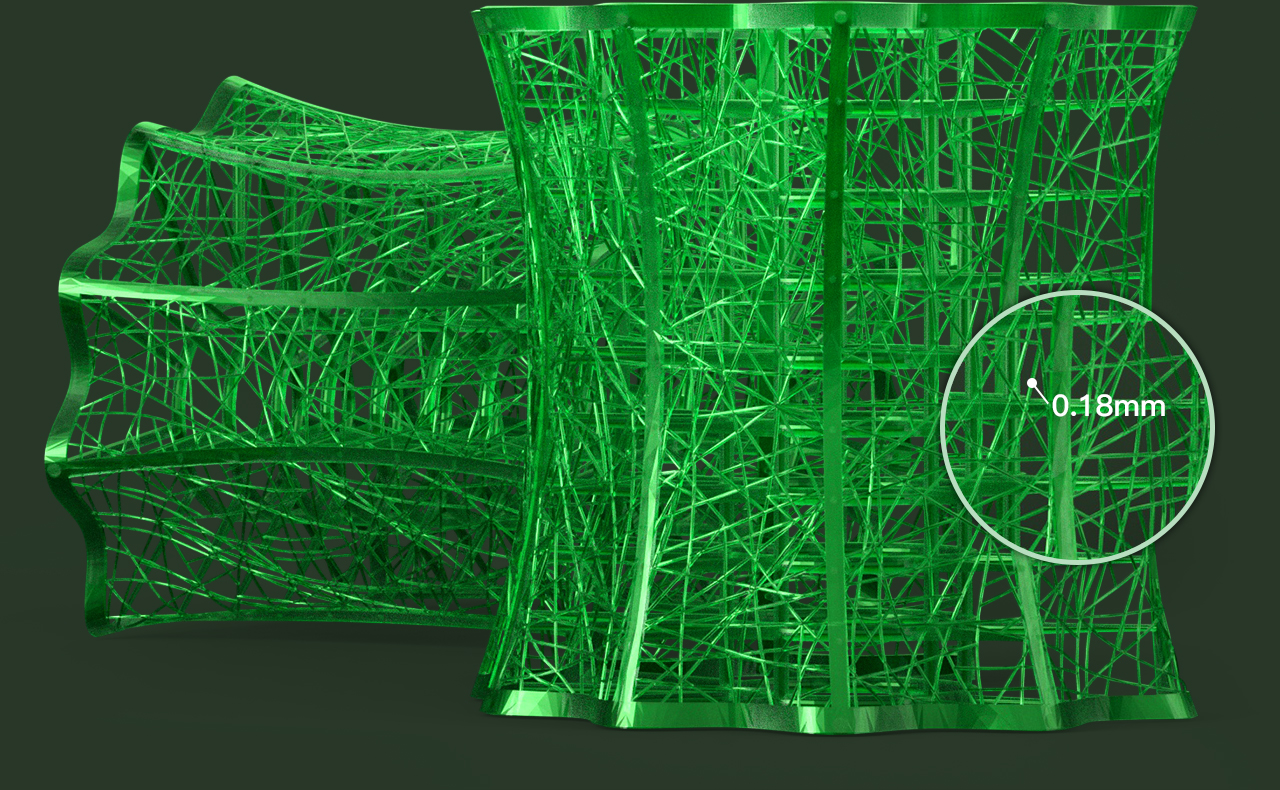

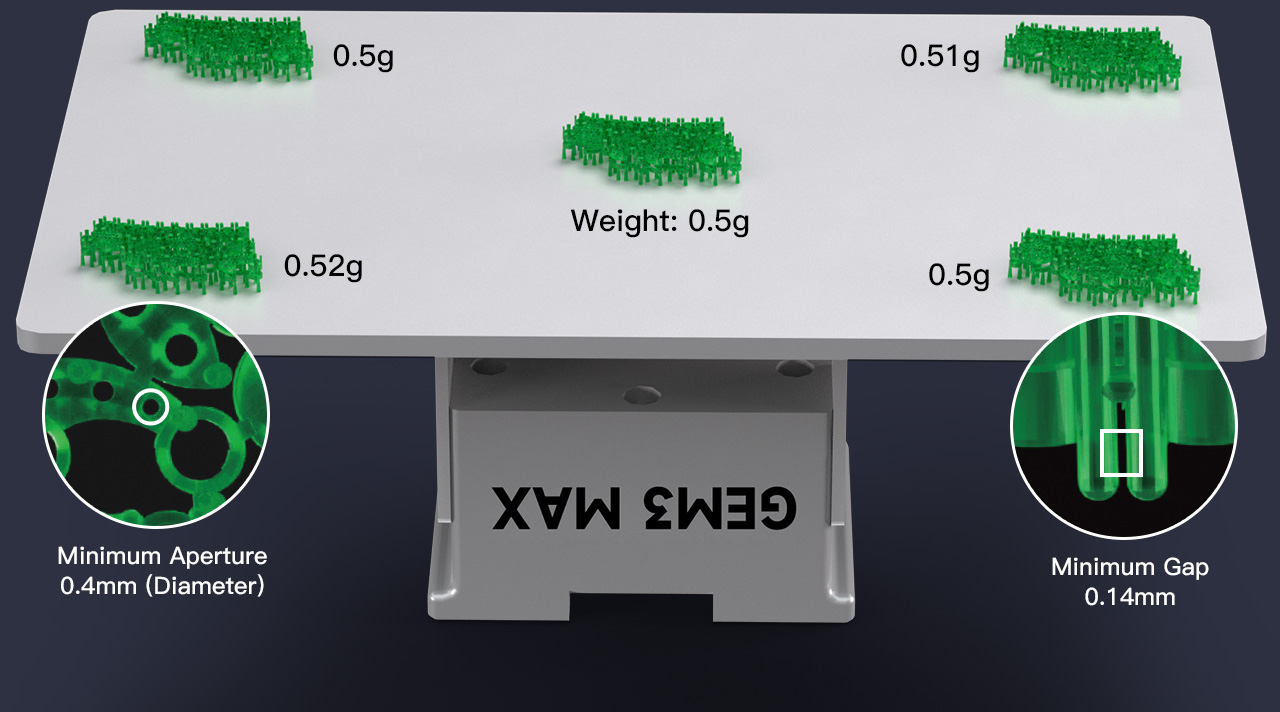

Zero-Deviation Casting: Advanced technology ensures perfect alignment between printed results and designs, with ±8μm wall uniformity. Verified by industrial 3D scanners, achieving ≥91% scan-to-CAD match rate.

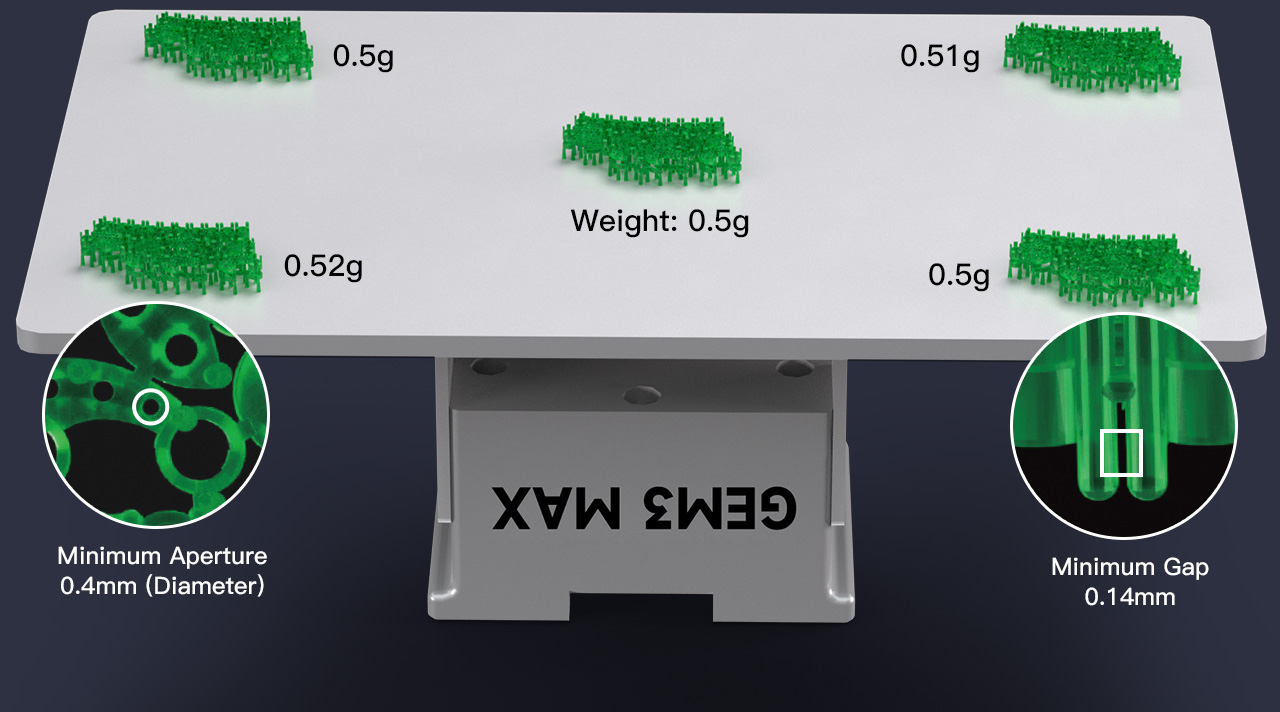

Exceptional Detail Resolution: Minimum aperture of 0.4mm and minimal gap of 0.14mm, capturing even the most intricate structures with precision. Guarantees exact replication from design to casting.

GEM3 Max - Your Reliable Jewelry Manufacturing Partner: Unleash creativity without constraints, where precision becomes effortlessly accessible.

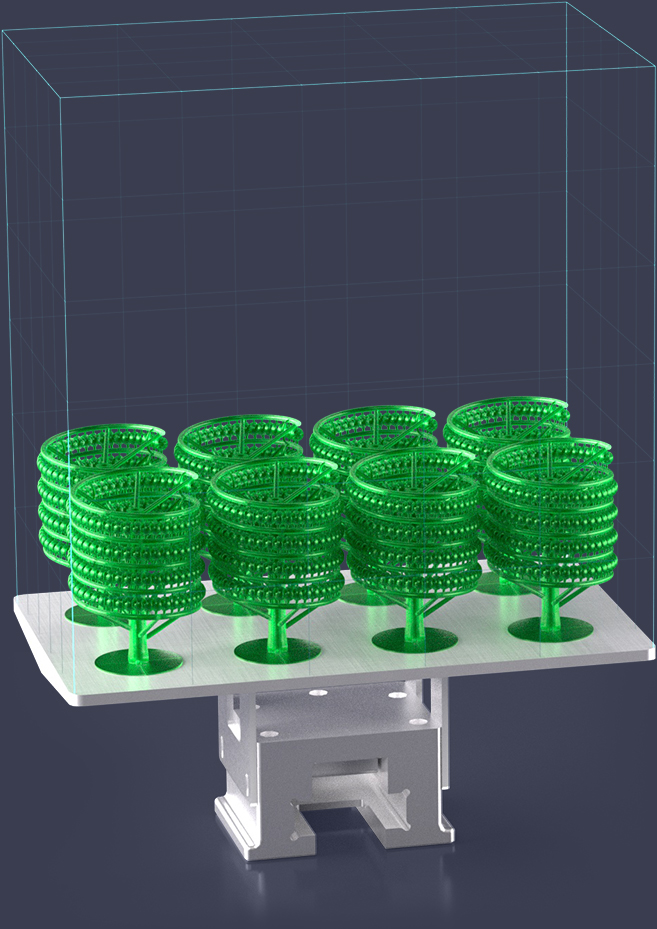

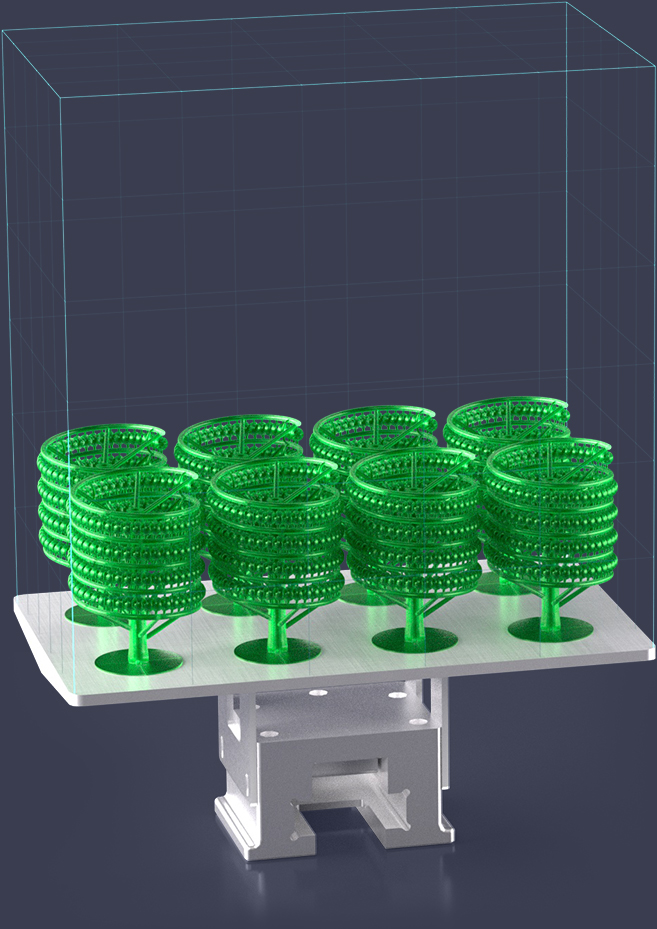

Mass Production with 99% success rate

Print 60+ rings, 20+ intricate designs (e.g., filigree, fusion) or 8 wax trees per plate Ideal for traditional designs, solid men’s rings, and jewelry masters for molding—quadrupling output for labs and workshops.

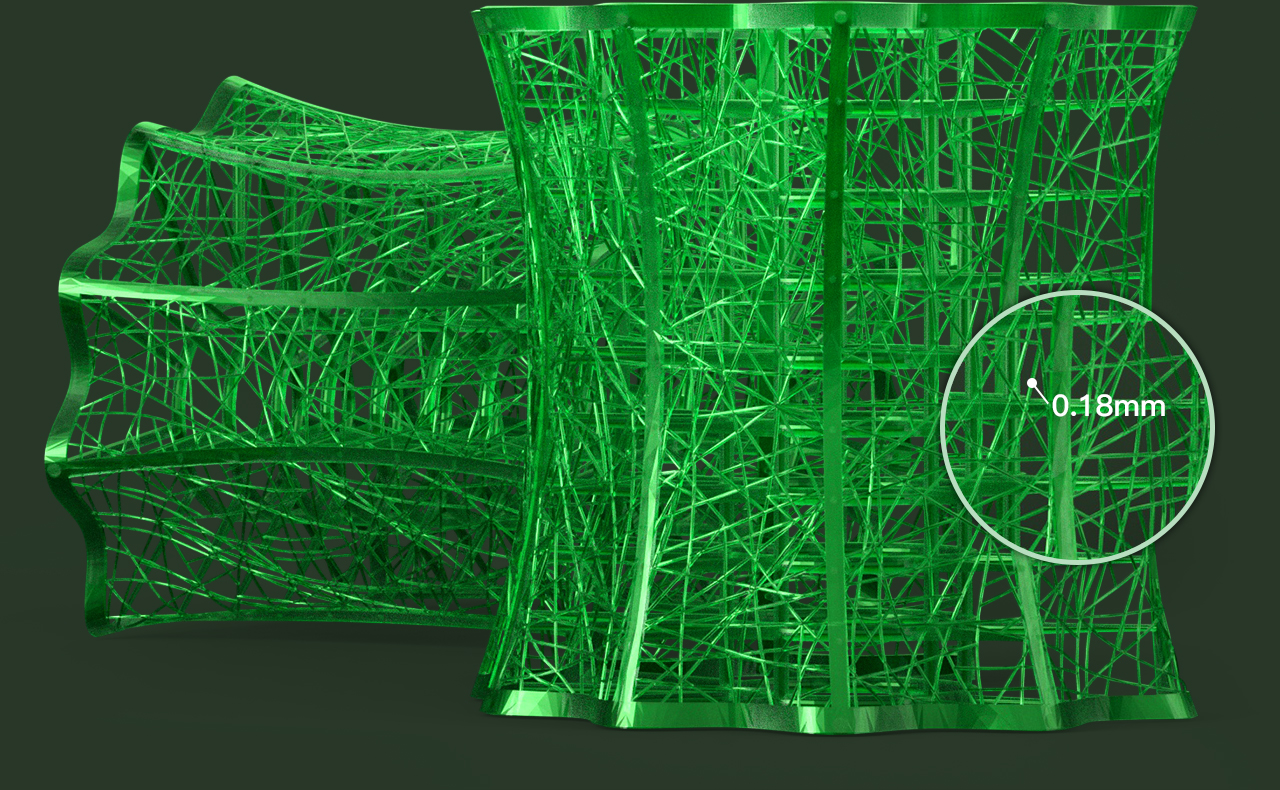

Micron-Level Precision for Intricate Designs

Ultra-HD exposure (15120×6230) guarantees high accuracy, flawlessly reproducing delicate details like micro-pave textures and ultra-thin walls (<0.3mm).

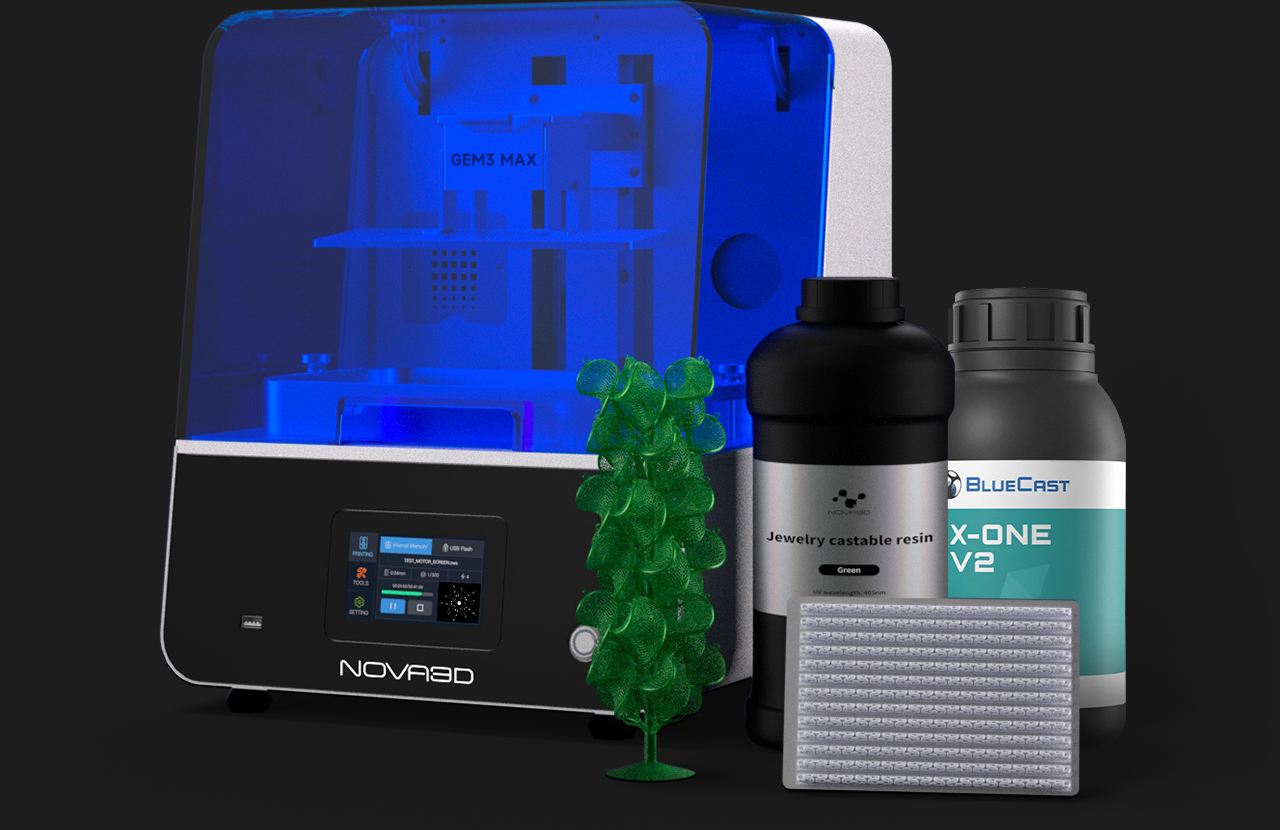

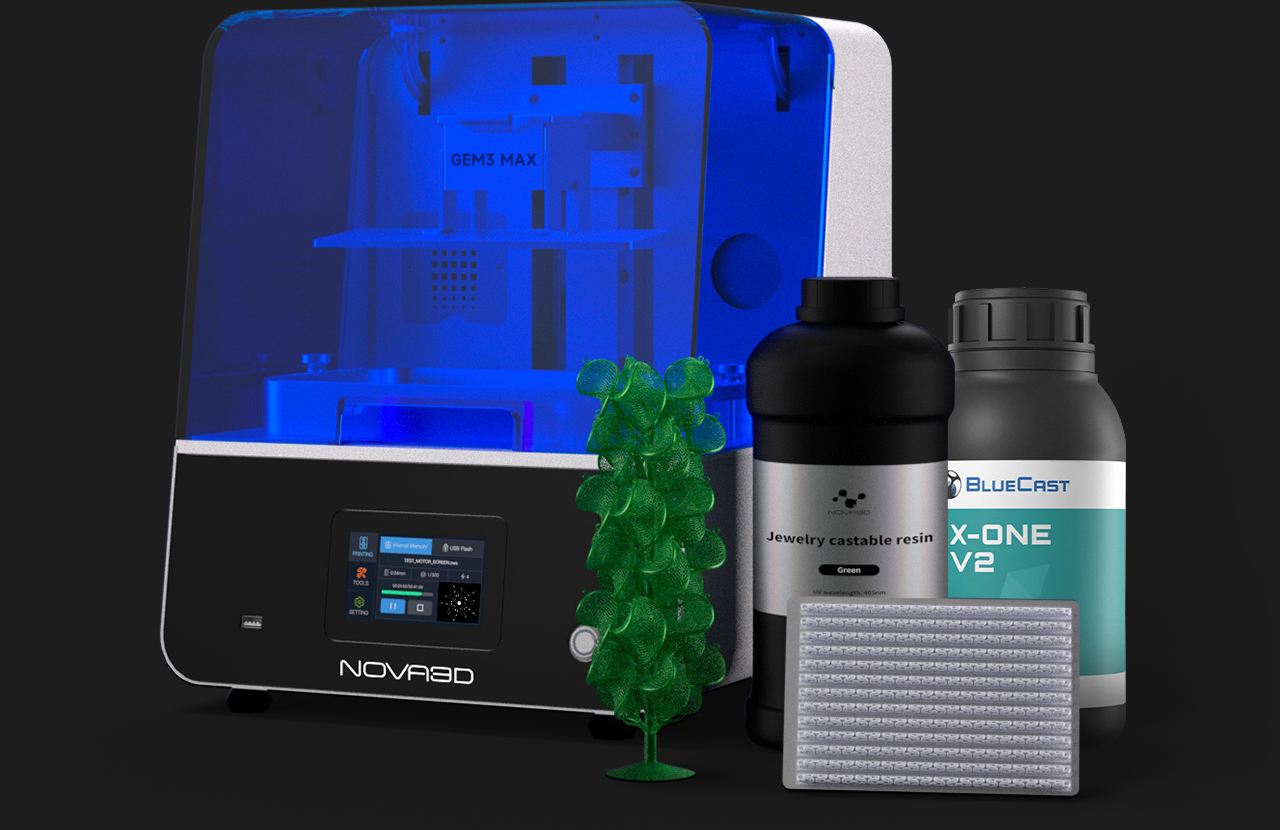

Open Material Ecosystem

Supports Nova3D and third-party castable resins like BlueCast resin series at $200/L, reducing material costs by 30% while ensuring burnout efficiency.

( BlueCast resin is recommended: http://www.bluecast.info )

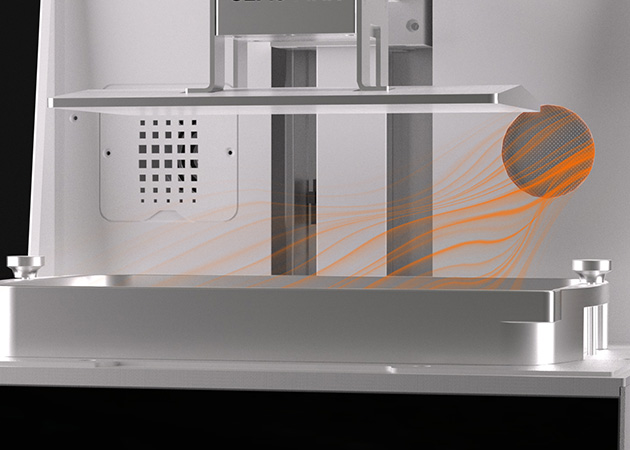

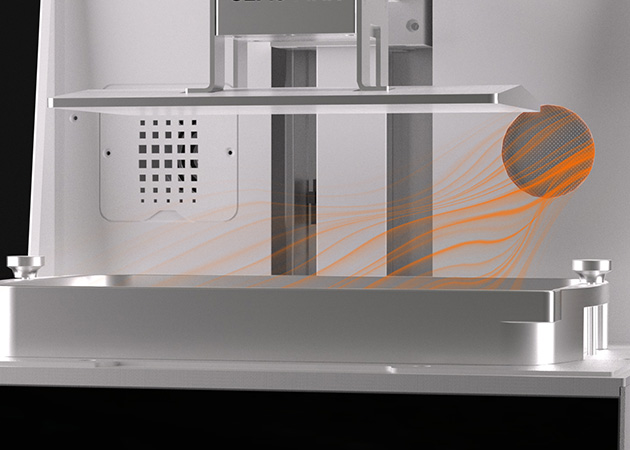

Precision Light Source for Uniform Quality

Patented optical system ensures uniform exposure across the entire build area, delivering CAD-perfect results every time.

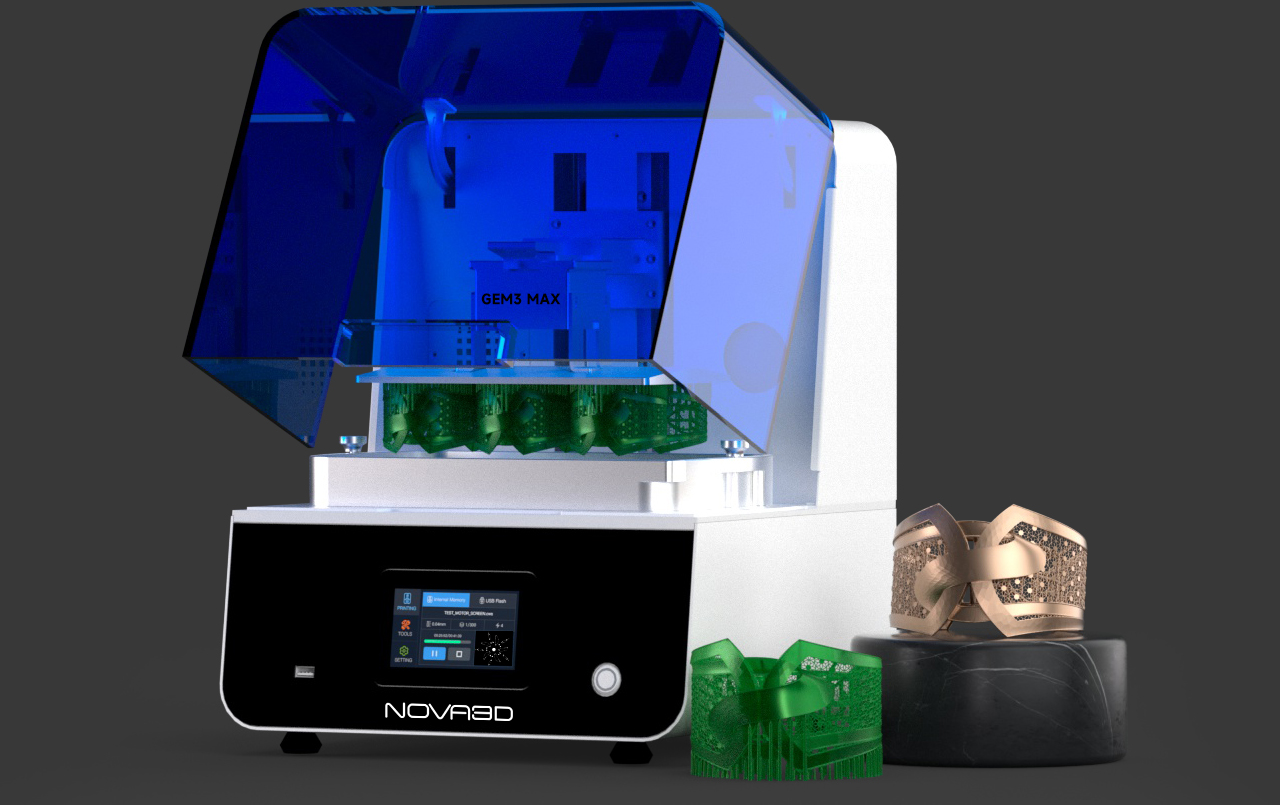

User-friendly and Easy to use

User-centric details make printing more convenient and safer.

-

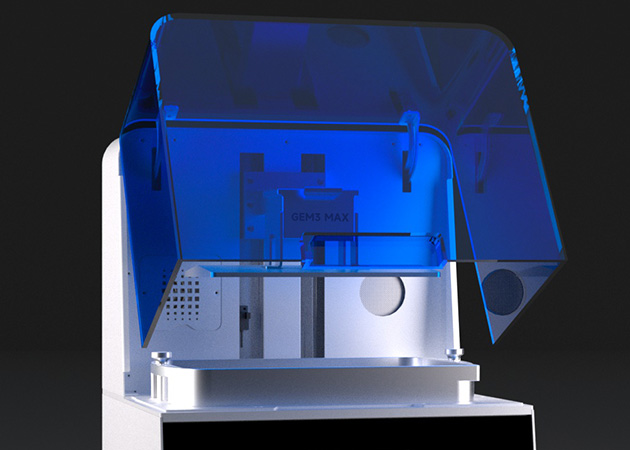

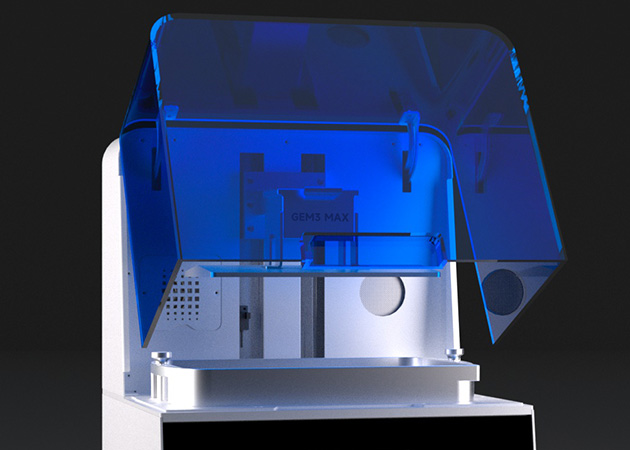

Flip-top design

-

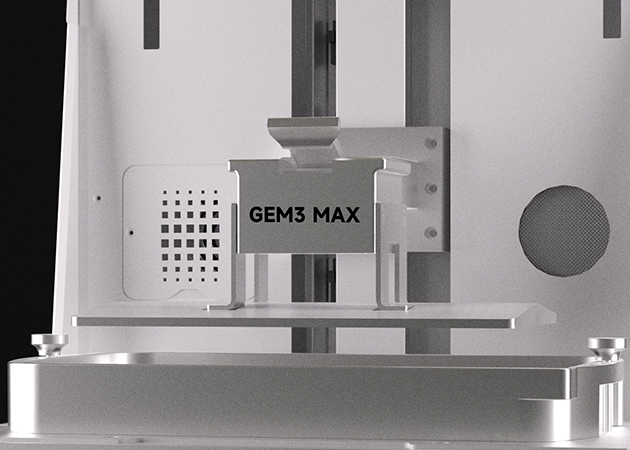

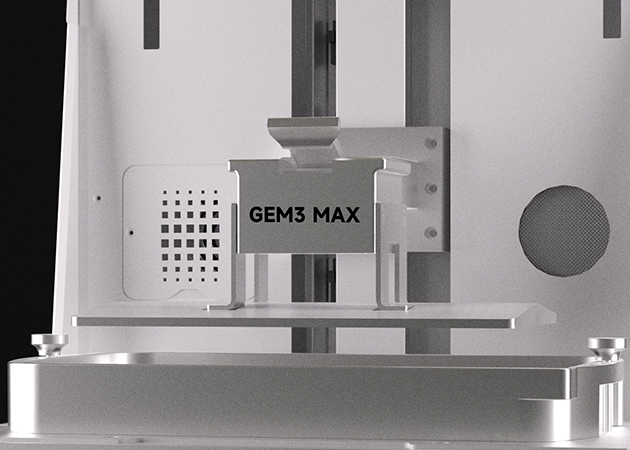

Press-type Platform

-

Chamber Heating

-

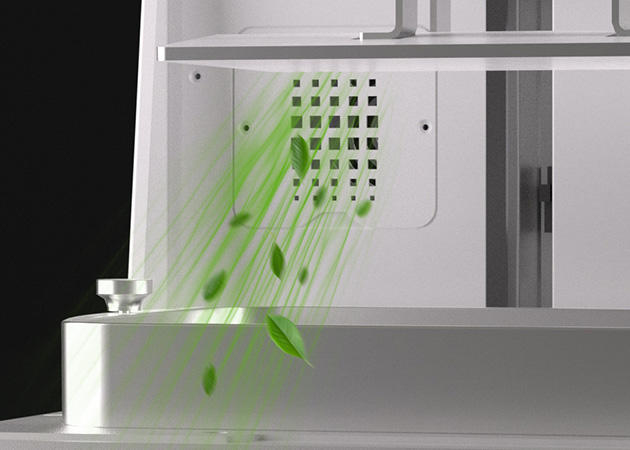

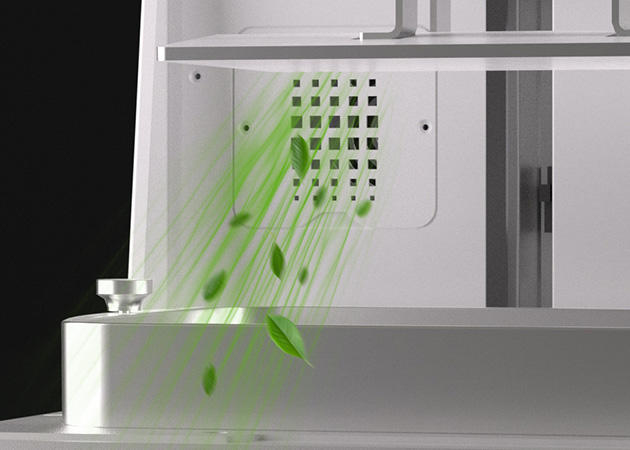

Air Purification

Plug-and-Play

4.3-inch touchscreen and auto-calibration enable mastery in 10 minutes.